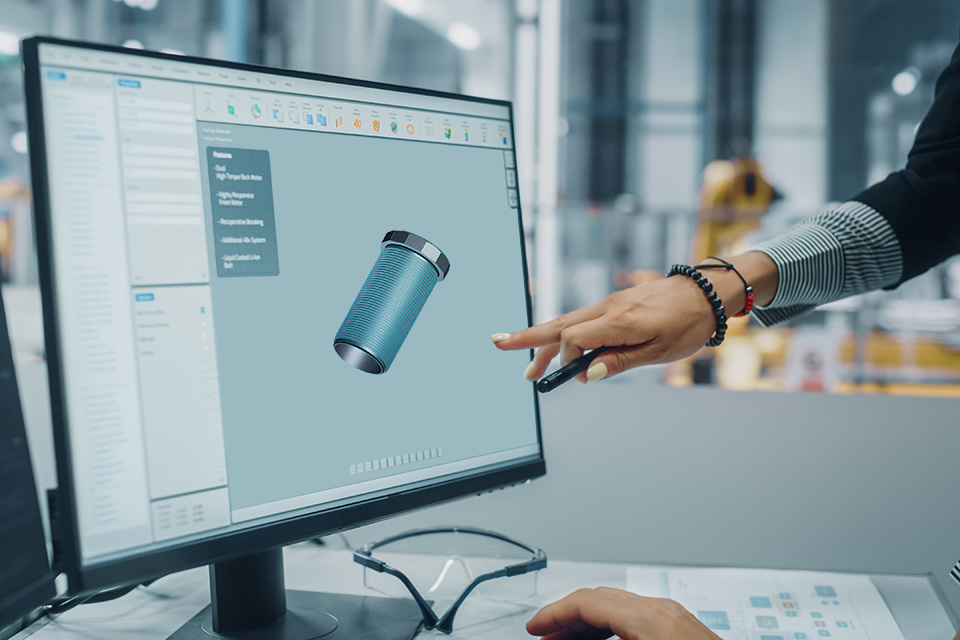

Development and construction

A driving force for innovation at

For example, when it comes to production techniques, manufacturing processes or material coordination for products, developers and designers, toolmakers and process mechanics are in constant exchange with each other

Development in this context is not just the one-off development of new products, but rather a permanent, iterative and cross-system process towards a “better” product, which, for the benefit of our customers, includes the product and the complete production process.

Exchange of experience, combined with modern working tools and continuous training and further education, ensure constant product development and progress in production technology in the area of our product range. New products are consistently created, existing ones are optimised and production techniques are improved on a broad basis.

This “know how” is of particular benefit to projects in which customised products are manufactured that are in the core area of our manufacturing techniques. Here we can offer our customers clear advantages.

Some technical features at a glance:

- Powerful modern equipments

- 2D + 3D design

- Filling and holding pressure simulations

- Photo-realistic reproduction (rendering)

- Construction of freeform surfaces

- Motion simulations

- Customer data can be processed via standard exchange formats, e.g. IPT, STEP, IGES, SAT, DWG, 3DS, ProE, CATIA